Idan kun kasance sababbi ga lif ɗin mu na Z, dole ne ku rikice cewa yadda ake shigar da irin wannan babban kayan aiki bayan an karɓa.Kada ku damu, da farko, koyaushe za mu kasance tare da ku don jagorantar ku yadda ake shigar da shi;na biyu, ga wasu ra'ayoyin da za mu raba tare da ku don shigar da lif ɗin guga da wuri.

1.Duba ko girman kowane bangare na chassis ya dace da tsawon kayan aikin da aka saya don sanin wurin da aka shigar da sassa daban-daban.

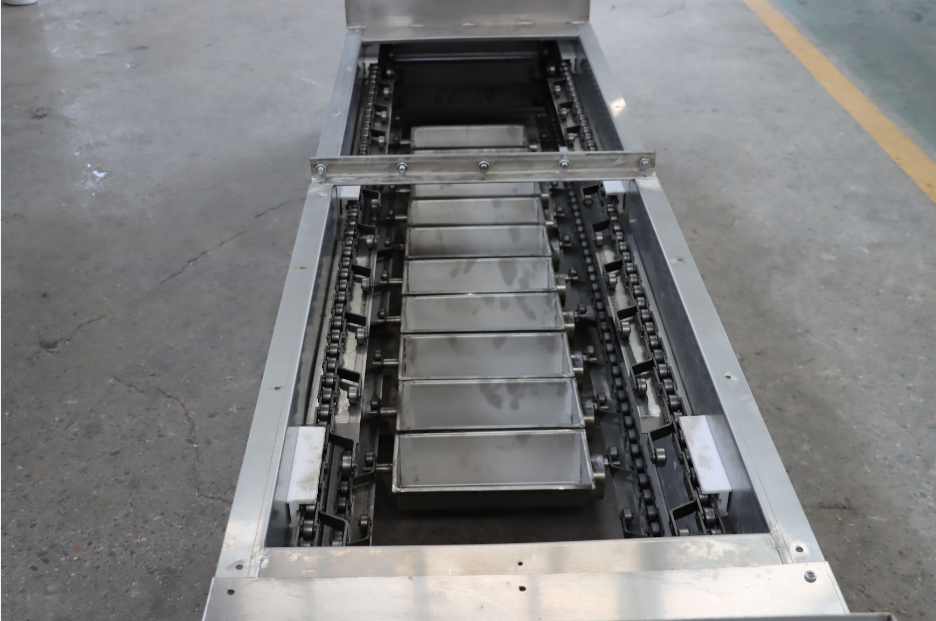

2.Duba sassa daban-daban na akwatin sprocket juyawa yana da sassauƙa don tabbatar da jujjuyawar sprocket ba tare da juriya ba.Don sprocket mai aiki, saboda an haɗa mai ragewa kuna buƙatar sakin iyakar juzu'i akan kusoshi sannan ana iya juyawa.

3.Kafin shigarwa, tabbatar da cewa tushe yana da ƙarfi sosai kuma ƙasa tana da lebur.Idan akwai wuri mara daidaituwa, da fatan za a daidaita tsayin matsayi daban-daban ta ƙafafu masu daidaitawa don tabbatar da cewa akwatin yana cikin yanayin kwance.

4.Bayan shigar da akwatin ya cika, da fatan za a duba gaba ɗaya madaidaiciya, idan daidai sai a duba ko wurin da kayan aikin ya dace daidai, idan ba daidai ba ne don Allah gyara, idan babu matsala sannan kuma mataki na gaba.

5.Don masu jigilar kaya tare da tsayi mai tsayi ko tsayi mai tsayi, ana buƙatar tsayawa akwatin a cikin matsayi mai dacewa tare da ginin da ke kusa da shi, tsarin karfe ko madaidaicin waldi na zaɓi don tabbatar da cewa mai ɗaukar kaya yana da kwanciyar hankali mai kyau, ba zai iya samun girgiza , Swing da haka kuma.

6.Lokacin da za a fara shigar da sarkar, da farko shigar da na'urar na'ura mai laushi ta kwance a cikin mafi guntu matsayi kuma tabbatar da tsawon sarkar kuma tsayin da ake bukata daidai ne.Ga gajeriyar sarkar masana'antar mu za ta haɗa ta kafin aikawa, don dogon sarkar da take buƙatar docking filin, hanyar docking daidai yake da sarkar talakawa.Lokacin docking, lura cewa ƙarshen madauwari na sarkar ƙungiyar yana cikin hanya ɗaya da jagorar gudu, kuma an hana ƙarshen buɗewa daga faɗuwa yayin aikin.Don tabbatar da cewa tsayin sarkar a bangarorin biyu na guda ɗaya, bisa ga shigarwa na shigarwa na jigilar kaya, za a ƙulla keɓancewa bayan sarkar, ba maɗauri ba, shirye don shigarwa na hopper.

7.A cewar jagorancin sarkar mai ɗaukar kaya don shigar da hopper daidai, kula da sashin buƙatun buƙatar shigar da jagorancin kurakurai na shigarwa zai haifar da lalacewa ga hopper, idan ba ku san shigarwa ba don Allah tuntuɓi tare da manufacturer don tabbatarwa.A cikin yanayin sarkar sako-sako , sarkar zuwa waje na akwatin don zama, sarkar sarkar da hopper a duka ƙarshen ramin daidai za a iya saka.Sanya hopper a nesa da juna kuma tazarar ita ce 127mm (ɗagawa lita 2.0).Juya sarkar, shigar da guga har sai duk shigarwar daidai ya cika, shigar da gajeriyar isarwa na iya jujjuya sarkar da hannu, don ƙarin buƙatar haɗa motar don shigar da hopper.

8.Bayan an shigar da hopper a cikin aminci, mai tayar da ruwa na bazara zai iya ƙarfafa sarkar don tabbatar da ƙarfafawa mai kyau, ba ma sako-sako ba ko kuma matsi.Duba ko tsayin sarƙoƙi guda biyu daidai ne, duba ko axis hopper tare da akwatin zuwa digiri 90, kamar tsayin sarkar bai dace ba, da fatan za a sake daidaitawa har sai sarkar a bangarorin biyu iri ɗaya, in ba haka ba za a yi rauni. sabon abu.

9.duba duk sassan bolts ko an ɗaure, idan sako-sako da fatan za a ƙara, tabbatar da daidai bayan mataki na gaba.

10.A duba mai rage man ya wadatar, yawanci a masana'anta an saka idan man bai isa ba don Allah a kara mai.Kula da canza murfin hular mai zuwa murfi mai numfashi don guje wa lalata ga mai ragewa azaman zafi.

11.Tighten da tightening limiter a kan kafaffen kusoshi, kunna wutar lantarki, na'urar fara gudu fanko.A cikin sa'o'i 2 gabaɗaya aikin yana santsi, hopper juye al'ada, duba bearings, motors, reducer, (Ba fiye da 30 ℃), duba tsawon sarkar aikin, ko hopper yana sassauƙa, saukewa yana da tsabta, ko akwai sauran gazawar, yana iya zama kayan ciyarwa a ƙarfin buƙata.

Lokacin aikawa: Nuwamba-21-2022